Practical Guide to Steel Columns & Beams (H/I Sections) for Light-Frame Structures

Steel columns and beams form the essential "skeleton" of countless industrial, agricultural, and commercial buildings. Using primarily hot-rolled or welded H-section and I-section steel, these components offer a robust, efficient, and adaptable solution for structures not designed to bear extremely heavy industrial loads.

1. The Core Material: H & I Sections

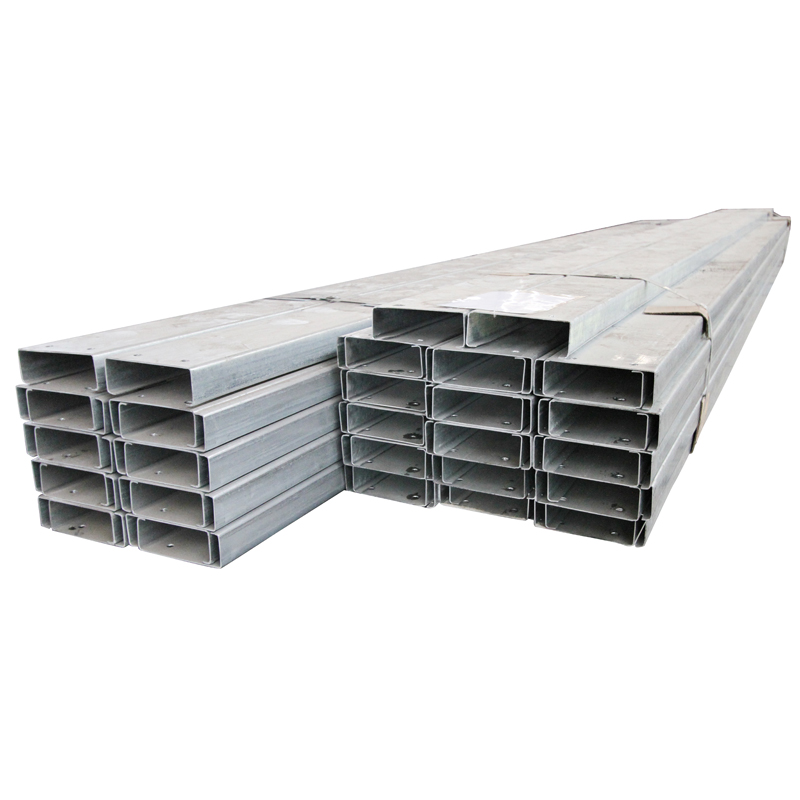

- Shape: These sections get their names from their cross-sectional profile resembling the letters "H" or "I". They feature two parallel flanges (top and bottom) connected by a vertical web.

- Manufacturing:

- Hot-Rolled: The most common method. Steel billets are heated and passed through rollers to form the precise H or I shape. Offers excellent strength and consistency.

- Welded: Fabricated by welding together separate steel plates (flanges and web). Used for larger or custom sizes not readily available as hot-rolled.

- Why H/I Sections?

- High Strength-to-Weight Ratio: Provide exceptional load-bearing capacity for their weight, making them efficient and easier to handle/maneuver.

- Structural Efficiency: The shape optimally distributes material to resist bending forces (beams) and compressive loads (columns).

- Versatility: Available in a wide range of standard sizes and weights to suit various span and load requirements.

- Ease of Connection: Flanges provide convenient surfaces for bolting or welding to other structural elements (purlins, girts, bracing, foundations).

2. Key Characteristics & Advantages

- Designed for Moderate Loads: Perfect for structures like workshops, warehouses, garages, exhibition halls, barns (chicken coops, cowsheds), etc., where the loads are primarily the building's own weight (dead load), snow, wind, light equipment, storage, or occupants (live loads). Not typically for multi-story heavy industry or large bridge spans.

- Speed of Construction: Pre-fabricated sections allow for rapid assembly on-site compared to concrete, significantly reducing project timelines.

- Large, Clear Spans: Enable wide-open interior spaces unobstructed by support columns, maximizing usable floor area – ideal for warehouses, halls, and agricultural buildings.

- Dimensional Stability: Steel doesn't shrink, warp, or creep like timber or concrete under typical environmental conditions.

- Predictable Performance: Steel's uniform properties and adherence to standards allow for precise engineering calculations.

- Adaptability & Future Modifications: Structures can be more easily extended, modified, or relocated if needed.

3. Essential Protection: Anti-Rust Treatment

Protecting steel from corrosion is critical for long-term durability and safety. Two primary methods are used:

- Painting:

- Process: Surface preparation (cleaning, abrasive blasting) is vital, followed by application of primer and protective paint systems.

- Pros: Wide range of colors for aesthetics, easier touch-ups, cost-effective for certain applications.

- Cons: Requires ongoing maintenance (inspection, repainting), lifespan is generally shorter than galvanizing, performance heavily depends on surface prep and coating quality. Best for interior or less harsh environments.

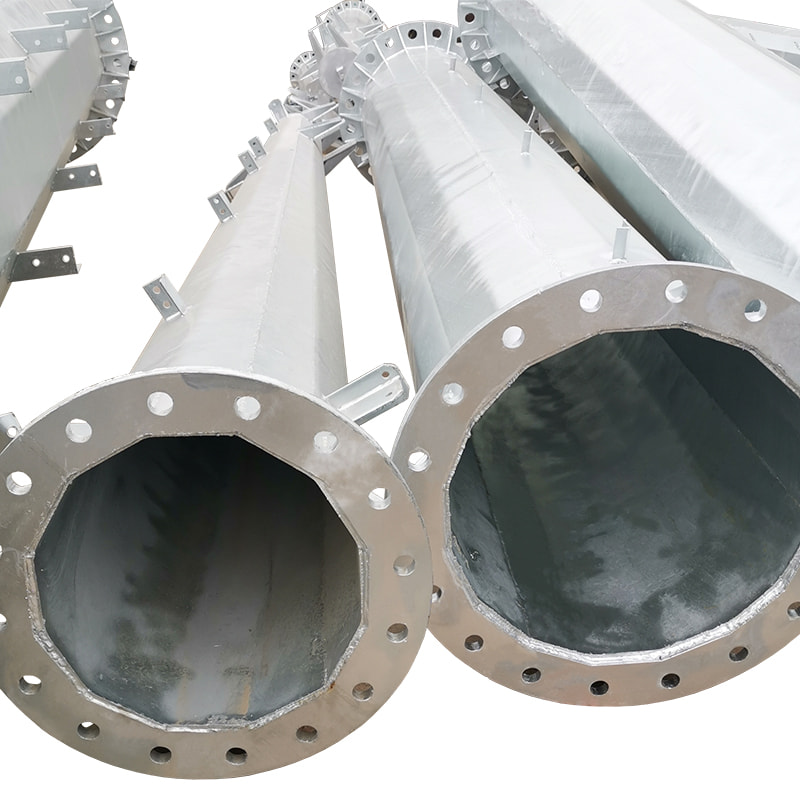

- Galvanizing (Hot-Dip):

- Process: Steel sections are immersed in a bath of molten zinc, forming a metallurgically bonded protective coating.

- Pros: Superior long-term corrosion resistance (decades of protection), very low maintenance, tough coating resistant to handling damage, excellent for harsh or humid environments (agricultural buildings, coastal areas).

- Cons: Higher initial cost than painting, limited color (silvery-gray), coating can be thick affecting tight tolerances, potential for drips/distortion on very large sections.

Recommendation: For agricultural buildings (chicken coops, cowsheds) with high humidity and potential corrosive agents, hot-dip galvanizing is strongly preferred.

4. Common Applications (Where They Shine)

These steel columns and beams are the backbone of:

- Single-Storey Industrial Buildings: Workshops, manufacturing units, packaging facilities.

- Warehouses & Logistics Centers: Distribution hubs, storage facilities requiring large clear spans.

- Commercial & Retail: Showrooms, automobile dealerships, exhibition halls, large retail stores.

- Agricultural Buildings: Barns, equipment storage, chicken coops, cowsheds, stables, machinery sheds.

- Community & Recreational: Sports halls, community centers, indoor riding arenas.

- Garages: Large vehicle repair shops, bus depots, fire stations.

- Aircraft Hangars: (Smaller, general aviation types).

5. Important Considerations

- Engineering Design: Essential. Always engage a qualified structural engineer. They will:

- Calculate the exact loads (dead, live, snow, wind, seismic).

- Select the appropriate H/I section sizes and grades of steel.

- Design connections (bolted/welded) and foundations.

- Ensure overall structural stability and compliance with building codes.

- Fabrication & Erection: Precision fabrication and careful erection by experienced crews are crucial for safety and structural integrity. Ensure connections are made exactly as per the engineer's drawings.

- Bracing: Lateral stability is vital. Proper bracing systems (roof cross-bracing, wall bracing, portal frames) must be included in the design to resist wind and other lateral forces.

- Fire Protection: While steel doesn't burn, it loses strength at high temperatures. Fire protection (intumescent paint, board systems, sprinklers) may be required depending on building use and regulations.

- Maintenance: Even with galvanizing or paint, periodic inspection for damage, corrosion (especially at scratches or connections), and structural integrity is recommended.

Hot-rolled or welded H-section and I-section steel columns and beams provide a strong, versatile, and rapidly constructed solution for a vast array of single-storey light to moderate-load structures like workshops, warehouses, garages, halls, and agricultural buildings.